Tyres mainly contain hydrocarbons that can be turned into small molecules of oil under the action of pyrolysis at high temperatures, so we can use the waste tyre pyrolysisl plants to turn waste tyres into fuel oil.

The waste tyres are piled in the open air for a long time, which not only occupie a large amount of land, but also easily breed mosquito-borne diseases, seriously aggravate the natural environment, destroy plants and vegetation, and seriously endanger the earth's ecological environment.

| ||

| The waste tyre pyrolysis plant |

Tyres are made of polymer elastomers, which are difficult for microbes to break down. Landfill, combustion and other solid waste treatment methods for waste tyres are not applicable. Therefore, how to deal with waste tyres has been recognized as a difficult environmental problem in the world.

Based on the fact that the main components of tyres are hydrocarbons, which can be pyrolyzed into small molecules of oil at high temperatures, DOING company developed the waste tyre pyrolysis plant, which can safely and environmentally turn the waste tyres into fuel oil.

|

| The waste tyre pyrolysis plant |

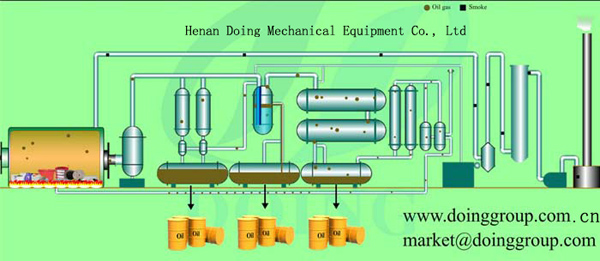

The main running process of the waste tyre pyrolysis plant as follows:

First, use the wire drawing machine to take out the tire wire, this step is to prepare for shredding the tires;

Second, put tires without hard steel wire into tire shredder to obtain small piece of tires, shredded tires are easy to pyrolyze;

Third, send the shredded tires into pyrolysis reactor through closed continuous feeder and heat the reactor with fuel. This step can realize automatic feeding, thus reduce labor cost and investment.

Four, when the pyrolysis reactor is heated to a certain temperature, oil gas will generate, then oil gas goes through three-step cooling system, including vertical condenser,horizontal condenser and cooling tower, to be cooled down to get oil and enter oil tanks;

Five, the non-condensable gas coming out of the cooling tower can be recycled to heat the reactor after being treated by tail gas cleaning and odor removal system;

Six, smoke will be generated during the burning of fuel, which can be discharged after being treated by the smoke cleaning system;

Seven, at last, the carbon black in the pyrolysis reactor can be collected by the carbon screw conveyor;

|

| The running process of waste tyre pyrolysis plant |

The pyrolysis oil can be used as fuel or further refined into diesel fuel. Using the waste tyre pyrolysis plant to turn waste tyres into fuel oil not only reduces the pressure on landfills but also has good economic and social benefits. Henan Doing provides two types of waste tyre pyrolysis plant: batch waste tyre pyrolysis plant and continuous waste tyre pyrolysis plant. If you are interested in waste tyre pyrolysis plant, you can contact us, our engineers will give you suitable solutions. welcome to consult.

Contact us for more detailed information

Whatsapp:+8613526692320

E-mail: sales@doingoilmachine.com

Tyres mainly contain hydrocarbons that can be turned into small molecules of oil under the action of pyrolysis at high temperatures, so we can use the waste tyre to oil recycling plant to turn old tyres into fuel oil.

How to turn old tyres into fuel oil?

How to turn old tyres into fuel oil?

The old tyres are piled in the open air for a long time, which not only occupies a large amount of land, but also easily breeds mosquito-borne diseases, seriously aggravates the natural environment, destroys plants and vegetation, and seriously endangers the earth's ecological environment.

Tyres are made of polymer elastomers, which are difficult for microbes to break down. Landfill, combustion and other solid waste treatment methods for waste tyres are not applicable. Therefore, how to deal with waste tyres has been recognized as a difficult environmental problem in the world.

Waste tyre to oil recycling plant installed

Waste tyre to oil recycling plant installed

Based on the fact that the main components of tyres are hydrocarbons, which can be pyrolyzed into small molecules of oil at high temperatures, DOING company developed the waste tyre to oil recycling plant. The waste tyre to oil recycling plant can safely and environmentally turn the old tyres into fuel oil.

The main process flow of the waste tyre to oil recycling plant to turn old tyre into fuel oil is as follows:

1. Heating waste tyres in the absence of oxygen, waste tyres in high temperature will melt, but not burn.

2. When the tyre melts, continue to heat, tyres will produce oil gas;

3. The oil gas through a cooling system will be condensed into liquid. Some hydrocarbon shorter length of the steam can not be condensed, will be retained as a gas (similar to propane).

4. Non-condensable gas is collected from the cooling system for heating the reactor or sold as fuel.

5. Collect the liquid oil into the oil tank;

6. Discharge carbon black and steel wire.

The main process flow of the waste tyre to oil recycling plant

The main process flow of the waste tyre to oil recycling plant

DOING's waste tyre to oil recycling plant can turn old tyres into pyrolysis oil. The pyrolysis oil can be used as fuel or further refined into diesel fuel.Using the waste tyre to oil recycling plant to turn waste tyres into oil reduces the pressure on landfills and reduces fossil fuel imports. It has good economic and social benefits.

- See more at: https://www.doinggroup.com/index.php?u=show-547.html#sthash.X5enGYAK.dpuf

Comments

Post a Comment