Waste tyre pyrolysis plant can convert waste tyres into fuel oil, carbon black and steel wire through pyrolysis technology under high temperature and oxygen-free conditions, which can effectively reduce the environmental pollution caused by the accumulation of waste tyres, and at the same time can gain profit by selling the products. Compared with intermittent waste tyre pyrolysis plant, Doing continuous fully automatic waste tyre pyrolysis plant has larger processing capacity, more intelligent operation and higher working efficiency, which can save large amount of manpower and material resources for customers.

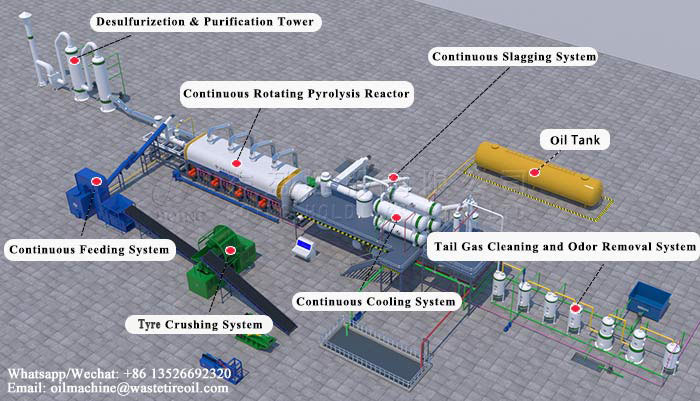

The composition of Doing continuous fully automatic waste tyre pyrolysis plant:

Doing continuous fully automatic waste tyre pyrolysis plant

Doing continuous fully automatic waste tyre pyrolysis plant

The whole continuous fully automatic waste tyre pyrolysis plant is mainly composed of feeding system, horizontal pyrolysis reactor, condensing system, oil tank, combustible gas recovery system, discharging system, tail gas purification system, flue gas purification system, pressure and temperature multi-point monitoring system, PLC electric control system, etc.

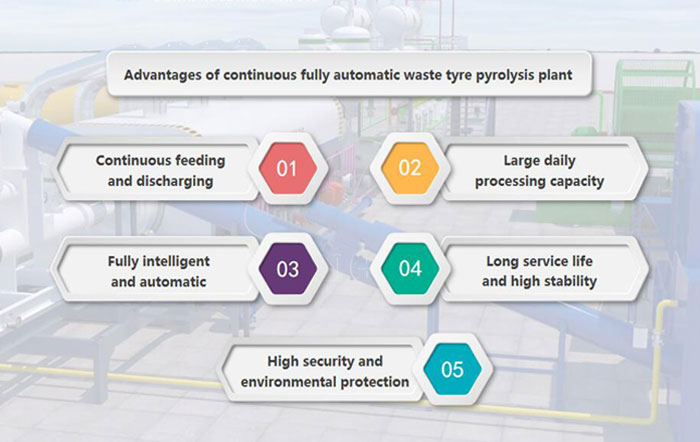

The advantages of Doing continuous fully automatic waste tyre pyrolysis plant:

Five advantages of Doing continuous fully automatic waste tyre pyrolysis plant

Five advantages of Doing continuous fully automatic waste tyre pyrolysis plant

1. Continuous feeding and discharging

For continuous fully automatic waste tyre pyrolysis plant, the feeding of raw materials and the discharging of carbon black are continuous. As long as you have enough raw materials, you can keep feeding without stopping, which can save feeding time and labor cost. What’s more, our carbon black discharging system adopts high temperature explosion-proof motor with cooling water jacket, carbon black can be discharged directly at high temperature and ensure the temperature of carbon black is below 50 degrees when discharging. In this way, the carbon black can be collected directly without waiting for cooling, saving a lot of time while ensuring continuous slag discharge.

2. Large daily processing capacity

The maximum daily processing capacity of a intermittent waste tyre pyrolysis plant is 15t. If you want to do a large project with intermittent waste type pyrolysis plant, you need to install multiple production lines, but the daily processing capacity of continuous fully automatic waste tyre pyrolysis plant can reach 30t-80t, which is suitable for large capacity projects and requires less land.

3. Fully intelligent and automatic

The continuous fully automatic waste tyre pyrolysis plant is equipped with various testing instruments, which can detect the temperature inside the furnace and pipeline in real time. The automatic feeding and slagging are also automatic and intelligent, which is more accurate and saves labor cost. Almost all of the running process are controlled by PLC electronic control system, and only 2-3 people are needed to operate a continuous fully automatic waste tyre pyrolysis plant.

4. Long service life and high stability

Continuous fully automatic waste tyre pyrolysis plant adopts indirect air heating protecting the pyrolysis reactor from heating by fire, which is more efficient and can help the pyrolysis reactor have a long service life and high stability.

5. High security and environmental protection

Each part of the continuous fully automatic waste tyre pyrolysis plant is sealed to ensure the whole operation process is safe and free from oil gas leakage and dust pollution.

Whatsapp:+8613526692320

E-mail: sales@doingoilmachine.com

https://www.wastetireoil.com

Comments

Post a Comment