Waste tire pyrolysis plant of Henan Doing is used for refining pyrolysis oil from waste tire. If you want to increase the pyrolysis oil yield, there are two main parts you need to pay attention.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

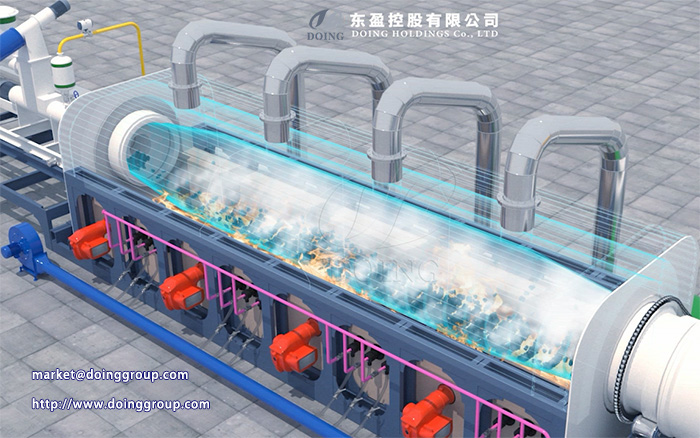

1.Control the temperature of the pyrolysis reactor

The pyrolysis reactor is the first and important part to convert waste tires into waste tire pyrolysis oil. You cannot obtain more waste tire pyrolysis oil at all, if the temperature of the pyrolysis reactor is too low or too high. There are two reasons. For one, oil gas can not comes out of the pyrolysis reactor if the temperature does not reach certain temperature(generally 160°C). Thus, you could not get waste tire pyrolysis oil.

Heating pyrolysis reactor

Heating pyrolysis reactor

Secondly, the temperature too high in the pyrolysis reactor will speed up the flow of oil gas. Then the fast oil gas flow has no enough time to be condensed into liquid oil. In this way, the pyrolysis oil yield would be low. All in all, if you want to get more waste tire pyrolysis oil, you should ensure the pyrolysis reactor heating to a reasonable temperature.

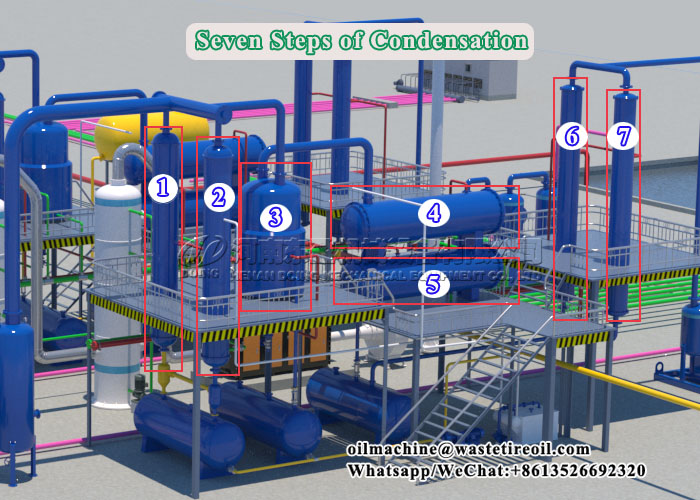

2.Good cooling system

Good cooling system can ensure that the waste tire oil gas under high temperature can be condensed into waste tire pyrolysis oil. The pyrolysis plant of DOING is equipped with 3-step cooling system. This 3-step cooling system can increase the contact area between oil gas, and condensers and the time to condense oil gas. Thus, the pyrolysis plant can produce more pyrolysis oil.

Cooling system

Cooling system

These two methods can help you get more pyrolysis oil in the production process. However, if you want high oil yield, it is also important to buy good waste tire refining plant. Henan Doing has been focusing on the research and improvement of waste tire refining plant quality and process for ten years, and has been far ahead in the industry, widely praised by users. Welcome to consult!

Comments

Post a Comment