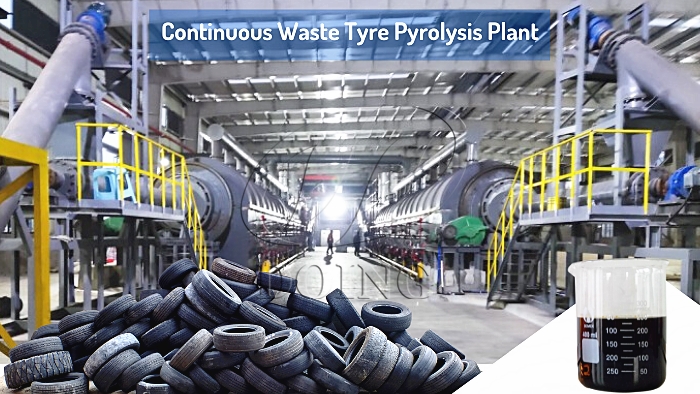

The continuous waste tire pyrolysis plant is equipped with an automatic feeding system and two sealed discharging systems, which makes it easy to operate. It not only can dispose 10-100 tons of waste plastics per day, but also can work continuously for 24 hours per day without a stop.

Continuous waste tire pyrolysis plant process

Continuous waste tire pyrolysis plant process

Continuous waste tire pyrolysis plant is the equipment line which can process waste tires to fuel oil, carbon black and steel wire for further use. As the vehicle increasing with the improving living standard, more and more waste tires generated every day. And waste tires as a solid waste not only occupy the land, the most important is it cause pollution to the environment. So how to dispose the waste tires becoming more and more necessary. That’s why we developed the continuous waste tire pyrolysis plant.

Working process of continuous waste tire pyrolysis plant

But at first the continuous waste tire pyrolysis plant is batch type, which has low automation and mainly operated by labour. This batch type pyrolysis plant needs to be stopped after every process for discharge residues (carbon black and steel wire) and feeding tires again. For one complete process, it takes about 16-20 hours, almost one whole day. And this batch type pyrolysis plant cannot process big quantity feedstock. For safety consideration, it only can process at most 12 tons tires per day. This is enough for the personal business. But for large scale waste tire dealing companies or government projects, this kind of batch type waste tire pyrolysis plant may not meet their demand. So, as the increasing demand of the market and improving technology, last year we just developed a new design as continuous waste tire pyrolysis plant.

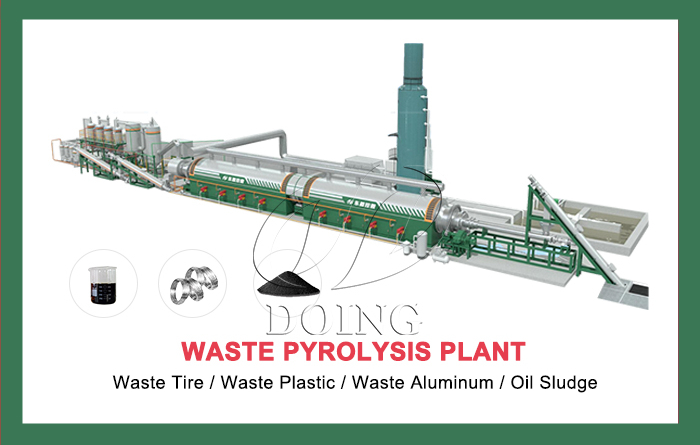

3 D picture of continuous waste tire pyrolysis plant

3 D picture of continuous waste tire pyrolysis plant

Advantages of continuous waste tire pyrolysis plant

This continuous waste tire pyrolysis plant is improved based on batch type pyrolysis plant, but has many improvements. It mainly has several advantages as below:

1.High capacity, which can process at least 10 tons waste tires per day, up to 100 tons waste tires per day;

2.Fully automatic with continuous feeding and discharge system;

3.PLC or computer control system, thus to save labour;

4.Multiple reactors design for fully pyrolysis to get high oil rate;

5.Indirect heating to prolong the usage life of the reactor;

6.Same as the batch type pyrolysis plant, it’s also applicable to process waste plastics.

Continous waste tire pyrolysis plant advantage

Continous waste tire pyrolysis plant advantage

If you want to know more informations about our continuous waste tire pyrolysis plant, please feel free to contact us. We DONG Company has specialized in waste tire pyrolysis project for about 8 years, we would like to provide valuable informations and suggestions to help you implement this project.

Technical data of Advantages of continuous waste tire pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Fuel oil application of continuous waste tire pyrolysis plant

Fuel oil application

Fuel oil application

The tire pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. With the demand of oil increasing, the price of pyrolysis oil will become higher and higher and you will make high profits. Carbon black and steel wire also have wide applications.

Comments

Post a Comment