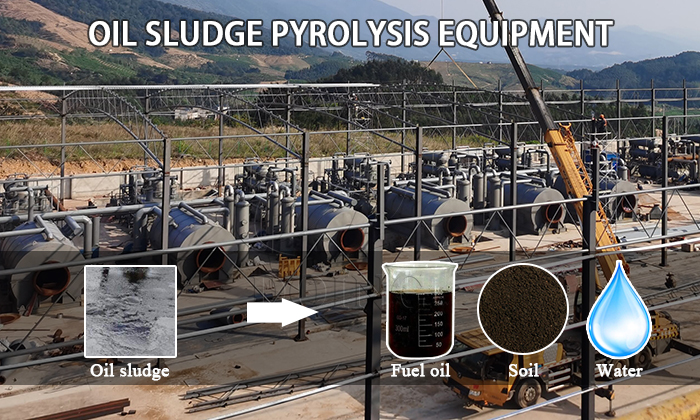

Oil sludge is a by-product of the petroleum production process that is mixed with water, oil, and solid sediment, and is a hazardous waste that can be harmful to humans and the environment. Proper disposal of oil sludge not only protects the environment but also creates fuel oil, which is why environmentally friendly recycled sludge has received much attention in various countries. Oil sludge pyrolysis equipment, with its advantages of thorough disposal and high energy recovery rate, has attracted extensive attention from researchers around the world. And our DOING company has developed oil sludge pyrolysis equipment that can dispose of oil sludge into fuel oil, water and soil in an environmentally friendly manner.

DOING oil sludge pyrolysis equipment

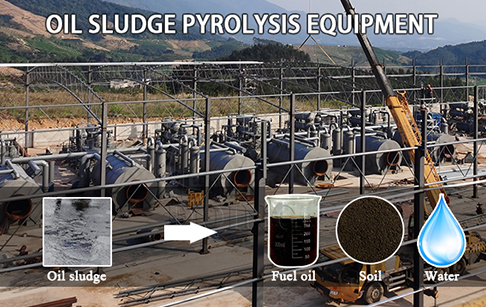

DOING oil sludge pyrolysis equipment

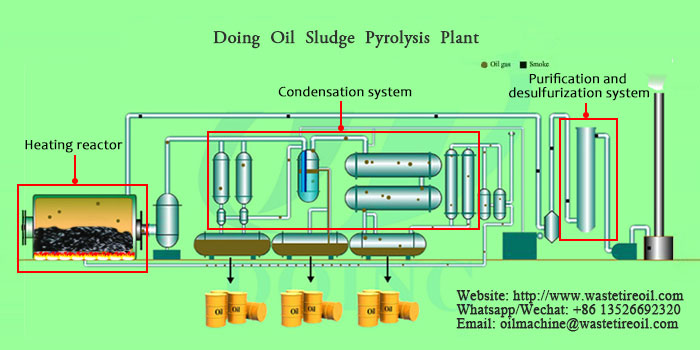

The process steps of oil sludge pyrolysis equipment

The work flow of oil sludge pyrolysis equipment

The work flow of oil sludge pyrolysis equipment

First, in the absence of oxygen, the oil sludge is loaded by a conveyor into a hydraulic feeder, which pushes the oil sludge into the pyrolysis reactor.

Second, the oil sludge is heated evenly driven by the power transmission device in the furnace.

Third, the heavy oil gas contained in the oil sludge are gradually extracted, and then the light oil gas are separated out from the dust and oil with low condensation point by the oil-gas separator, after which the oil and gas are condensed into liquid fuel oil, water and non-condensable gas by the condensation system.

Fourth, the non-condensable gas can be recovered to assist heating reactor in the furnace after the water are removed in the water-sealed tank.

Fifth, the liquid fuel oil is collected in the oil tank after passing through the oil-water separator.

Last, the flue gas generated in the furnace will be purified by a flue gas cleaning system, which has three steps to ensure compliance with environmental standards.

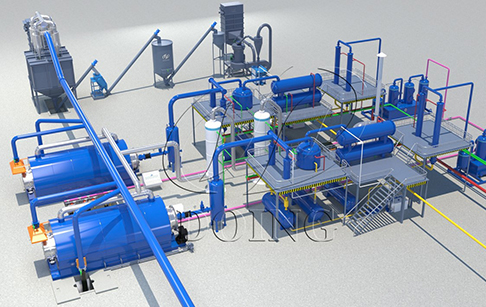

To meet customers’ different requirements, we have designed four types of batch oil sludge pyrolysis equipment. And they are DY-1-6, DY-1-8, DY-1-10, DY-1-20. We can provide continuous oil sludge pyrolysis equipment as well. What’s more, we can also customize the oil sludge pyrolysis equipment according to your situation. Here are the specific parameters for your reference.

| Technical parameter of oil sludge pyrolysis equipment | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

If you are interested in oil sludge pyrolysis equipment, please feel free to give your inquiry in the form below. We will reply you in 24 hours.

Leave a message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Oil Sludge Pyrolysis Plant

Products

Project Case

The small skid-mounted 100KG/D pyrolysis plant ordered by the Mexican customer has been delivered

The small skid-mounted 100KG/D pyrolysis plant ordered by the Mexican customer has been delivered Small scale 100kg/d waste plastic pyrolysis plant and crude oil distillation plant were delivered to Australia

Small scale 100kg/d waste plastic pyrolysis plant and crude oil distillation plant were delivered to Australia Two sets of 15TPD aluminum plastic pyrolysis plant were successfully installed in Liaoning, China

Two sets of 15TPD aluminum plastic pyrolysis plant were successfully installed in Liaoning, China 4 sets of 12TPD waste tire pyrolysis plant successfully put into operation in Liaoning, China

4 sets of 12TPD waste tire pyrolysis plant successfully put into operation in Liaoning, China 4 sets of 12TPD waste tire pyrolysis plant installed in Guangxi, China!

4 sets of 12TPD waste tire pyrolysis plant installed in Guangxi, China! Two sets of 12TPD waste tire pyrolysis plant were installed in Guangxi, China

Two sets of 12TPD waste tire pyrolysis plant were installed in Guangxi, China 30TPD full continuous waste tire pyrolysis machine project installed in Kazakhstan!

30TPD full continuous waste tire pyrolysis machine project installed in Kazakhstan! Two sets of 50TPD full continuous waste tire pyrolysis plant project installed in Yunnan, China!

Two sets of 50TPD full continuous waste tire pyrolysis plant project installed in Yunnan, China! Waste pyrolysis and distillation plant projects installed by DOING in India

Waste pyrolysis and distillation plant projects installed by DOING in India Waste pyrolysis and distillation plant projects installed by DOING in Nigeria

Waste pyrolysis and distillation plant projects installed by DOING in Nigeria

FAQ

Instructions for developing waste tire pyrolysis plant project in Bangladesh

Instructions for developing waste tire pyrolysis plant project in Bangladesh What factors will affect waste tire pyrolysis plant cost?

What factors will affect waste tire pyrolysis plant cost? What is the floor area of waste tire pyrolysis machine? How should the waste tire pyrolysis plant be planned?

What is the floor area of waste tire pyrolysis machine? How should the waste tire pyrolysis plant be planned? The best Kuwait waste tire recycling solution: setting up waste tire pyrolysis plant projects

The best Kuwait waste tire recycling solution: setting up waste tire pyrolysis plant projects How to choose a competitive pyrolysis apparatus fabricator?

How to choose a competitive pyrolysis apparatus fabricator? How can we reuse and recycle used vehicle tires?

How can we reuse and recycle used vehicle tires? Why are the costs of transporting goods in Africa so high?

Why are the costs of transporting goods in Africa so high? Where can I purchase high quality tire packing machine?

Where can I purchase high quality tire packing machine? Is full-continuous waste tire pyrolysis plant a profitable business in India?

Is full-continuous waste tire pyrolysis plant a profitable business in India? How much does a set of waste oil distillation plant cost?

How much does a set of waste oil distillation plant cost?

Comments

Post a Comment